Mimaki, the expert and leading brand of large format inkjet printing machines, cutting plotters and 3D printing machines, is expanding its product range in two of the most popular series of the recent period. By adding the UJV100-160Plus printing machine to the 100 Series and the UCJV330-160 integrated printer/cutter machine to the 330 Series, Mimaki provided its users with the opportunity to increase their printing quality and flexibility while offering more efficiency and lower energy consumption. These two new UV roll-to-roll printing models, which offer numerous production advantages to users, also expand the range of applications and open the doors to more business opportunities. Acting with the vision of a sustainable future in the printing and advertising industry, Mimaki continues to introduce new solutions to the market within this framework.

Emphasizing its pioneering role in this field by introducing the first white ink UV printer to the market in 2004, Mimaki continues to develop versatile UV technologies that print high-quality industrial advertising graphics and expand its portfolio. The models in the entry-level 100 Series, which were introduced to the market a few years ago, and the 330 Series, which focuses on more advanced and high-volume work, managed to gain great appreciation from users in a short time, thanks to their features that fully meet different market demands with the power of Mimaki Core Technologies. These innovative series also contributed to the digital transformation process in the industrial advertising industry, solving the changing needs of printing professionals and producing more profitable jobs.

New UV printing solutions have access to PICT, Mimaki's new cloud-based press status monitoring tool. Users can easily download PICT, which is designed to increase the efficiency of Mimaki users' printing processes and production management. Thanks to this tool, users can instantly monitor the operating status and performance of their printing machines from a PC or mobile device. In this cloud application, the operation and ink usage results of the printing machine are recorded for each Mimaki printing machine in production or in designated groups, providing users with advanced ink inventory management, maintenance and production planning.

UV printing technologies are being adopted faster in the industry

Mimaki emphasizes its commitment to transforming the printing and advertising industry into a more sustainable structure with the newly added UJV100-160Plus and UCJV330-160 models to its portfolio. These two UV printing machines contribute to the environment as well as their users with their productivity and energy consumption levels.

Mimaki Eurasia General Manager Arjen Evertse pointed out that the adoption of UV printing technologies is accelerating throughout the industry due to both demands for more sustainability and increasing energy prices. Evertse; “Thanks to the instant curing of UV-LED inks, much less energy is used during the UV printing process compared to other technologies. “This both improves the environmental impact of the printing process and saves production costs and delivery times.”

Evertse continued his words as follows; “As Mimaki, we are committed to supporting the transition to UV technology in the market to ensure a more sustainable and efficient printing process, to future-proof our valued users' businesses and, of course, to strengthen sustainability for all of us. In this context, the UJV100-160Plus and UCJV330-160 models are the latest in our efforts to expand the UV printing options available to print service providers. “These new printing machines also offer their users the unique benefits synonymous with Mimaki technologies.”

The advantages of UV printing in industrial advertising work increase even more with UCJV330-160

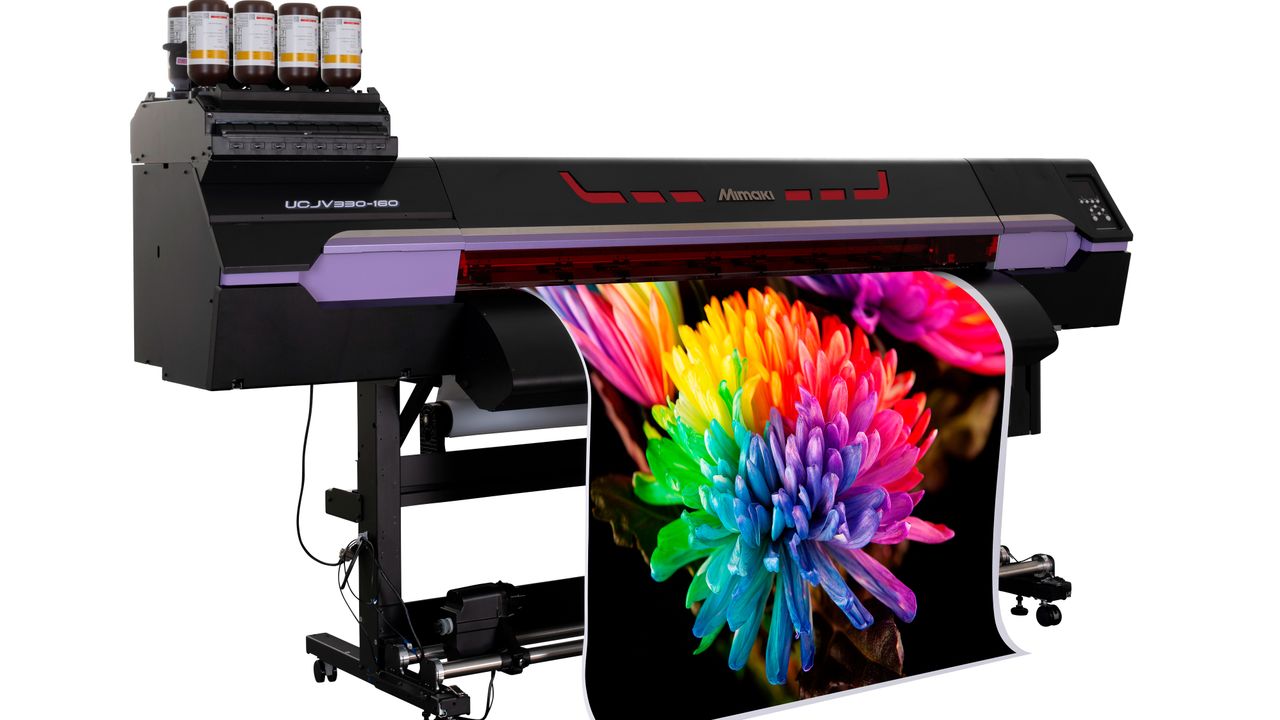

New to the 330 Series, the UCJV330-160 UV-LED roll-to-roll integrated printer/cutter offers significantly improved productivity, print quality and versatility for industrial advertising graphics applications. Capable of reaching practical speeds of 28m2/hour with its four-color configuration or 18m2/hour with white and/or lacquer paint, the model enables users to offer impressive delivery times to their customers and produce more jobs with higher efficiency. In addition, the new printing machine, which does not compromise on print quality despite high speeds, has a newly developed dye spraying technology that reduces color irregularities in high-density areas even in high efficiency mode.

UCJV330-160 expands application and material flexibility to support Mimaki users' transition to non-PVC, more environmentally friendly materials. The new UV printing machine is available for basic color inks as well as white and l

It was decorated with white paint. In this way, users can perform high-quality prints on milky white (translucent), transparent and colored materials, as well as on traditional materials used for outdoor industrial advertising graphic applications. Among the materials users can print on, PET, PU (polyurethane) and other resin films, fabric and paper (including uncoated paper) stand out.

This material flexibility, combined with advantages such as 2.5D printing, watermark or 5-layer printing options, creates new application opportunities with high added value for printing professionals. With 2.5D printing, it can create leather-like textured surfaces on a shoe or handbag. Watermark prints prepared with lacquer dyes can reveal different printing effects under different light conditions. Layered prints made with the UCJV330-160 can improve printing on transparent or colored film and create tactile and visual effects.

Equipped with advanced features for contour (edge) cutting that allows applications such as stickers, embellishments and labels, UCJV330-160 provides users with more time savings with automatic switching from printing to cutting mode.

High efficiency and lower energy consumption become reality with UJV100-160Plus

UJV100-160Plus, the new model of the 100 Series, which is appreciated by the entry-level segment, offers its users the advantage of more efficiency and lower energy consumption. Designed to consume extremely low amounts of power, the new model consumes only 0.5kW of energy. This figure corresponds to less than half the power demanded by eco-solvent and latex printing machines on the market. While energy efficiency has a positive impact on operating costs, it also helps reduce CO2 emissions.

Thanks to the new features of UJV100-160Plus, users can expand their product portfolio with new applications while increasing their operational and cost efficiency. The new ink saving function added to the UJV100-160Plus reduces ink consumption by up to 50% while maintaining the color balance of the printed design. Dye reduction levels can be easily adjusted and changed by the operator using RasterLink7 software. Therefore, there is no need for special knowledge or equipment for color adjustment.

The 'pull-back printing function' in this new UV printing machine allows it to print up to 3 layers by retracting the printed material. This printing feature allows for colour-white-colour or white-colour-varnish printing, giving users greater flexibility to offer customers a wide range of applications. Mimaki users can achieve different applications and profitable works with 3-layer printing, which they can also perform with lacquer paints.

The roll-to-roll UV-LED printer UJV100-160Plus also connects seamlessly with Mimaki's CG-AR plotter series. This new, practical advantage increases workflow efficiency by allowing users to send cutting data directly from RasterLink7 to the plotter. When integrated with a CG-AR cutting plotter, UJV100-160Plus performs automatic printing and cutting with minimal operator intervention, thanks to Mimaki's advanced cutting technology ID Cut function.